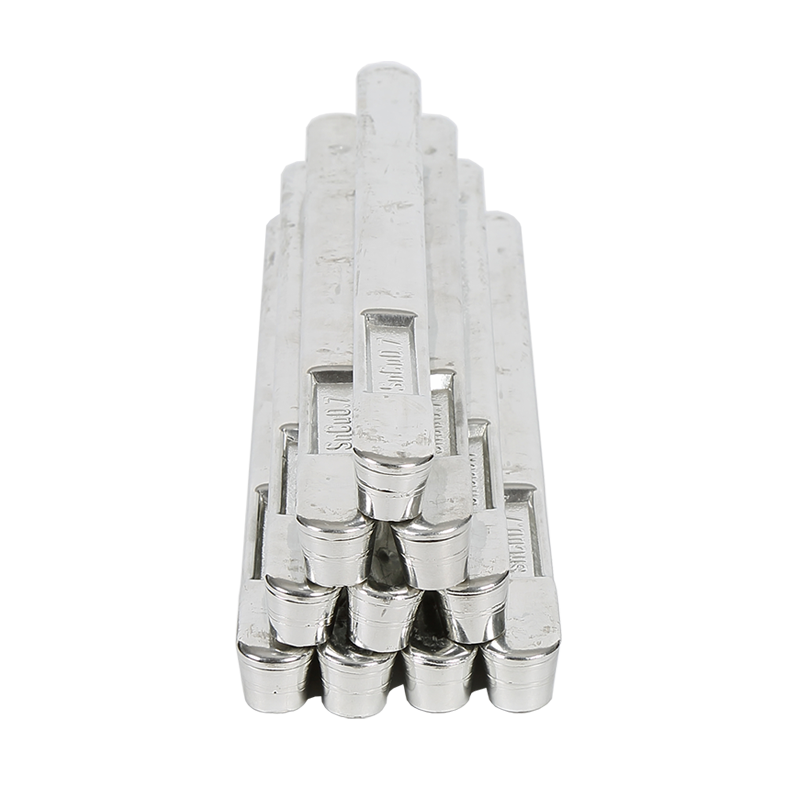

Our Sn99Ag0.3Cu0.7 lead – free solder wire and solder bar, also known as SAC0307 high – melting – point lead – free solder, have a composition of 99% tin, 0.3% silver, and 0.7% copper. According to customer requirements, the lead content is usually less than 100 ppm.

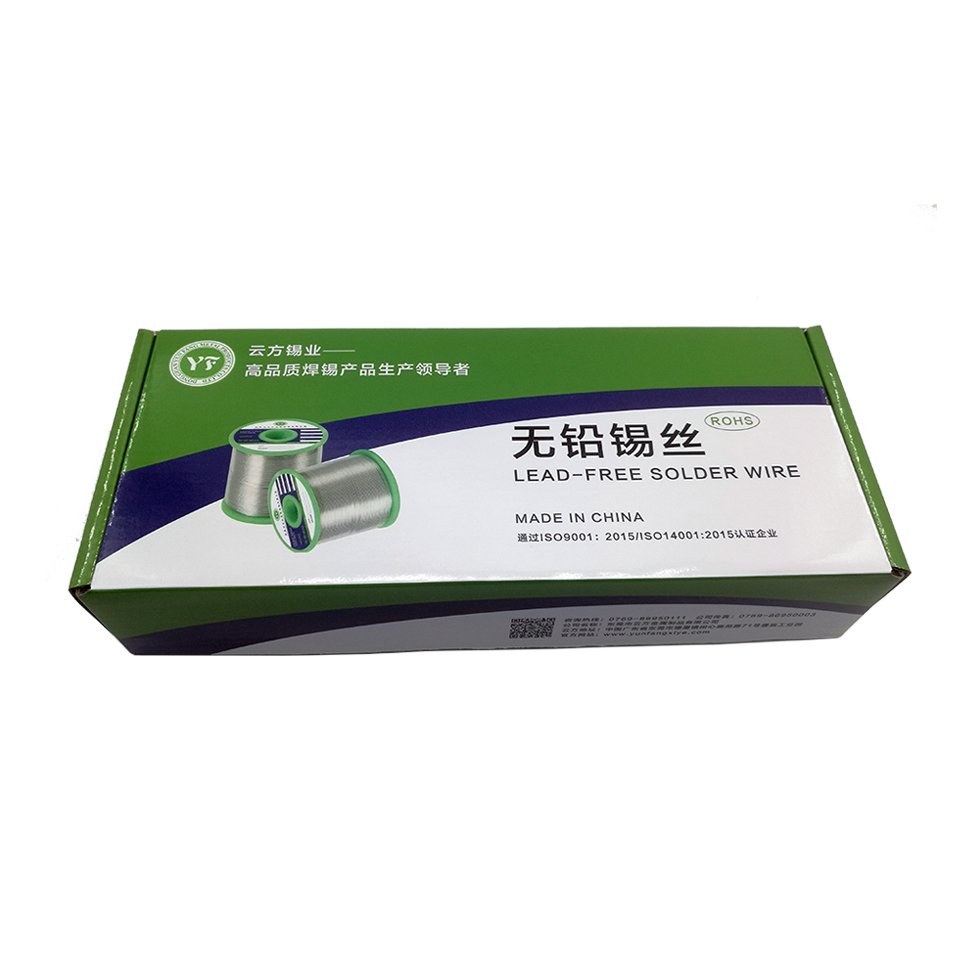

The lead – free solder wire produced by yunfang Tin Industry Solder Company has flux as the core material, with an addition amount generally around 2%. The wire diameter can reach above 0.15mm. The material selection process strictly follows the RoHS directive and SS – 00259 standard. All processes from raw material smelting, mixing, inspection to pouring are carried out using high – standard production processes.

Our environmentally friendly lead – free solder uses two different raw materials, including electrolytic lead with a refined lead content of 99.99% and No. 1 tin with a purity exceeding 99.97%. Due to the addition of copper, this Sn99Ag0.3Cu0.7 solder wire can make electronic components generate a relatively high resistivity during the soldering process.

Super – strong Anti – oxidation and Deformation Resistance

The combination of three different alloy components makes this lead – free environmental – friendly solder wire have a high melting point, be not easy to soften, and greatly enhance its anti – oxidation ability.

Excellent Soldering Effect, Fast Soldering Speed, Good Wettability, and Fluidity

The active flux in this product can provide superior soldering assistance.

| Chemical Components | ||||||||||

| Sn | Ag | Cu | Pb | Sb | Bi | Zn | Fe | Al | As | Cd |

| Residue Content | 0.3±0.1 | 0.7±0.2 | < 0.1 | < 0.1 | < 0.06 | < 0.001 | < 0.02 | < 0.001 | < 0.03 | < 0.002 |

Physical Properties

| Alloy Component | Melting Point, ℃ | Tensile Strength, g/cm3 | Rigidity HB | Heat Conductivity M.S.K | Tensile Strength, MPa | Elongation Rate, % | Electric Conductivity, % |

| Sn99Ag0.3Cu0.7 | 230 | 7.4 | 9 | 64 | 32 | 48 | 16.0 |