New Product

Product Category

Fluxes & Other Products

Flux is designed to facilitate the soldering process. It is a chemical substance that protects the surface and prevents oxidation on the metals being soldered. The surface remains unchanged before and after the soldering process. Flux is a natural soldering material with rosin as its main component.

Lead Free Solder Wire and Solder Bar

Leaded Solder Wire and Solder Bar

Sn25Pb75 tin – lead solder wire and solder bar have a wide range of applications. They are used in electrical products such as thermal fuses, power semiconductors, and calculators. The solder wire is especially suitable for soldering materials like stainless steel, zinc alloys, and aluminum lamp caps. In the automotive and electronics industries, it is commonly applied to the soldering of fans, wires, and automotive printed circuit boards.

Our Sn40Pb60 tin – lead solder wire and solder bar have a melting point of around 200 °C and offer stable soldering performance. Our company combines years of production experience with cutting – edge technologies. We’ve introduced German direct – reading spectrometers to strictly control quality and use high – purity tin alloys as raw materials to ensure product quality.

Our Sn50Pb50 solid tin – lead solder wire and solder bar feature reliable performance. They have a melting point of approximately 200 degrees Celsius and a working temperature of 250 degrees Celsius. The Sn50Pb50 indicates that the alloy used in this solder wire and solder bar contains 50% tin and 50% lead respectively.

Our Sn60Pb40 water – soluble tin – lead solder wire and solder bar are popular and highly demanded products. Boasting a melting point of 189 degrees Celsius, they deliver remarkably stable soldering performance. The Sn60Pb40 composition indicates that the alloy in both the solder wire and bar consists of 60% tin and 40% lead.

The Sn63Pb37 no – clean tin – lead solder wire and solder bar are highly versatile. They are suitable for high – precision electronics, where pinpoint soldering is crucial. They also serve well in the soldering of common electronic products. Additionally, they are an excellent choice for the automotive and electronics industries, ensuring reliable connections in a wide range of manufactured goods.

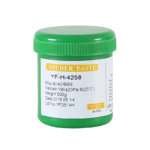

Solder Paste (Syringe Packing and Bottle Packing)

Our Sn42Bi58 for LED is a typical low – temperature lead – free solder paste. Its alloy consists of 42% tin and 58% bismuth. The operating temperature is divided as follows: preheating temperature ranges from 90°C to 110°C, the melting point is 138°C, and the reflow soldering temperature ranges from 150°C to 100°C.